PS80 Wafer Spin Cleaner

High Energy Spin Cleaning Increases Epitaxial and Diffusion Process Yields

The precise molecular construction required in semiconductor devices makes contamination a major cause of production losses.  Foreign contamination existing on semiconductor surfaces during high temperature processes is particularly bad. The contamination will prevent the proper crystal structure from developing in epitaxial deposits and it can be diffused into the base crystal structure, deteriorating its electronic characteristics. In either case, the damage is permanently ingrained and irreparable.

Foreign contamination existing on semiconductor surfaces during high temperature processes is particularly bad. The contamination will prevent the proper crystal structure from developing in epitaxial deposits and it can be diffused into the base crystal structure, deteriorating its electronic characteristics. In either case, the damage is permanently ingrained and irreparable.

The PS80 provides a highly effective cleaning technique for wafers prior to high temperature processes and following the use of polishing compounds. The technique consists of high energy mechanical "scrubbing" action on the surface of the wafer while the surface is being rinsed and cooled by a clean, pure fluid.

This technique takes very little time, partly due to the rapid drying at high rpm following the final rinse.

FEATURES

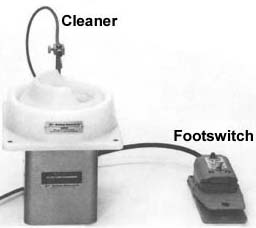

- Footswitch controlled for simple operation

- Rugged, heavy duty construction

- Large handling capacity -- up to 6.5"

- Coordinated fluid dispensing

- Unpressurized fluid storage

- Variable speed

- In-line fluid filter

- Convenient vacuum chucks

- Automatic dynamic braking

- Positive motor protection

- Portable or recessed mounting

PS80 Equipment

|

|

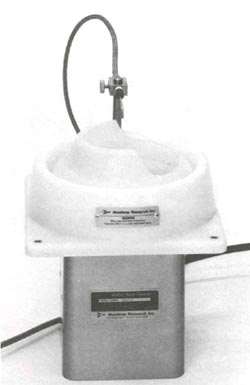

Cleaner Assembly - The cleaner assembly houses the motor, motor speed controller, vacuum solenoid valve, and connectors for footswitch and solvent storage/dispense system. The upper bowl is molded, high density polyethylene with a removable splash deflector. An integral drain system carries away the excess fluids. A support rod provides adjustable positioning for the dispense nozzle.

|

Footswitch - The footswitch is a THREE LEVEL SWITCH that controls VACUUM, SPIN and DISPENSE. The On/Off switch and the pilot light are located on the top of the footswitch which is a heavy duty, totally sealed design.

Note: PS80 Cleaner can be used as a dryer and purchased without the dispense arm and nozzle assembly. Contact the factory for more information.

|

Optional Tachometer P/N 2-24382

|

|

Operating Features

|

|

Simple Operation, footswitch controlled - The PS80 is designed for operating simplicity. The three level footswitch controls the cleaner's three fundamental functions: FIRST LEVEL: Applies vacuum to the chuck to hold the wafer. SECOND LEVEL: Starts the motor which causes the wafer to spin at the pre-set speed. THIRD LEVEL: Dispenses the cleaning fluid in a steady stream onto the center of the spinning wafer.

Rugged, Heavy-duty construction - The PS80 is a heavy-duty, industrial quality machine. The Teflon dispenser line is protected by stainless steel braid and the footswitch is a heavy-cast, totally sealed design. This cleaner is designed for long life under severe use applications.

Coordinated fluid dispensing - The three-level footswitch provides coordinated fluid dispensing. The third level of the footswitch activates dispensing and, when released, gravity suck back prevents dripping between cycles. Gravity refill technique recharges the pressure container. Low dispense pressure is applied to the fluid only during the actual dispense time. If the HRI Safety dispense system is not used, the third level footswitch voltage is provided at a connector to operate your dispense valve.

Unpressurized fluid storage - The main chamber is never pressurized. Pressure is applied only to a small fluid-filled sub-chamber.

Variable speed - A speed control located on the bottom of the cleaner assembly provides a speed setting at any RPM from 500 to 5,000.

|

In-line fluid filter - A stainless steel Microporous filter with 2 micron typical and 10 micron absolute characteristic is located on the outlet of the fluid storage dispense system.

Convenient vacuum chucks - A wide range of standard or special vacuum chucks are available for your application.

Automatic dynamic braking - When the footswitch is released, automatic dynamic brakes quickly bring the motor to a stop.

Positive motor protection - Teflon shaft seals, vacuum chuck overhang skirt design, integral bowl drainage system and other devices protect the motor from cleaning fluids.

Compact design, portable or recessed mounting.

|

Typical Operating Cycle

The wafer to be cleaned is placed on the vacuum chuck. Operator depresses the 3-level footswitch, which:

FIRST LEVEL: Applies vacuum to the chuck to hold the wafer.

SECOND LEVEL: Starts the motor which causes the wafer to spin at the pre-set speed.

THIRD LEVEL: Dispenses the cleaning fluid in a steady stream onto the center of the spinning wafer.

Following mechanical action, the operator keeps the footswitch fully depressed and allows the wafers to rinse briefly. The operator then releases the footswitch to the SECOND LEVEL which stops fluid dispensing but continues the spinning for rapid drying. FIRST LEVEL only applies vacuum to the chuck.

A cotton swab or polishing cloth is manually moved across the wafer surface, generating a high friction cleaning action, aided by the mechanical rinsing, dissolving and cooling action of the fluid.

Spin speed may be set at any RPM from 500 to 5,000

Specifications:

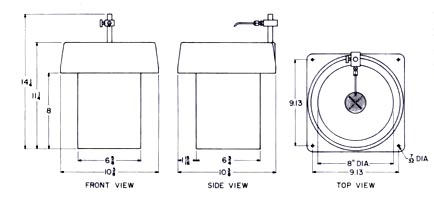

- Size: See above outline drawing

- Bench cut-out size: 6 3/4" x 6 7/8"

- Shipping Weight: 45 pounds

- Power: 2 amp, 115V, 100V, or 230V, 50 or 60 Hz

- Vacuum: 23" Hg machine running

- Pressure: 20 to 40 psi at 1cfm, N2 or clean air with Solvent Storage/Dispense System

- Speed: Variable

- Bowl and splash collector: High-density polyethylene

- Dispenser line: 6 ft. Teflon with armored stainless steel braid

Foreign contamination existing on semiconductor surfaces during high temperature processes is particularly bad. The contamination will prevent the proper crystal structure from developing in epitaxial deposits and it can be diffused into the base crystal structure, deteriorating its electronic characteristics. In either case, the damage is permanently ingrained and irreparable.

Foreign contamination existing on semiconductor surfaces during high temperature processes is particularly bad. The contamination will prevent the proper crystal structure from developing in epitaxial deposits and it can be diffused into the base crystal structure, deteriorating its electronic characteristics. In either case, the damage is permanently ingrained and irreparable.