This model was developed specifically for R&D applications when relatively large and/or heavy substrates need to be processed by spinning, but in a simple sequence, at the lowest possible cost.

The PWM202 controller can drive either one of two motors to its full 1/2 horsepower capability. The BD2 motor will spin twice the inertial load of the BD5 motor up to 2,500 rpm. The top speed of the BD5 motor is 5,000 rpm. The BD2 has been used to spin an inertial load as large as a 14" diameter aluminum plate, 3/8" thick. Both motors are dc servo motors with a vacuum-thru-the-shaft design for vacuum chucks and potentially a substrate lifter, working through the motor shaft.

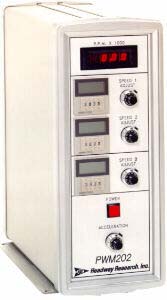

The acceleration/deceleration ramp is adjustable over a range of approximately 0.5 to 4.0 seconds from zero to max speed. The three sequence timers can be set to one of two ranges: 0.1 to 99.9 or 1 to 999 seconds or minutes or hours! The sequence is: Timer 1 at Speed 1, then Timer 2 at speed 2, then Timer 3 at Speed 3. A +24 vdc output from each timer is available externally, for actuating dispense functions or other peripheral devices during the active time of that timer.

The PWM202 system is typically built into the LS22 or IT22 style of cabinet (22" I.D. bowls), although the BD motors can be used on the smaller CB15 style bowl (15" I.D.) in special situations.

The PWM202 can control simple 1 and 2 fluid type accessory dispensers. If more complex sequences or more complex dispensing features are needed, then the microprocessor MP100 controller, is recommended. The MP100 utilizes the same PWM motor driver as the PWM202, but the MP100 can control long sequences of events, control more I/O for complex functions such as moving arms and complex dispensing functions, save recipes for future re-use, etc. (at a slightly higher price).

PWM32 Microprocessor Sequence Controller | PWM202 Sequence Controller | MP100 Controller